I must admit, I’ve had two very prevalent fascinations over the past year or so: Sound suppressors and running a .300 Blackout AR-15 pistol with an aftermarket piston system. The first fascination compliments the second fascination, so the two marry especially well. However, the second fascination is the problematic player in the relationship. I can make (and have made) a piston driven AR-15 with an 8” .300 Blackout barrel cycle supersonic ammunition just fine, but anyone who knows anything about shooting .300 Blackout knows that the real magic happens when subsonic ammunition meets Mr. Sound Suppressor. The problem lies in lower pressure causing cyclic unreliability.

The question I get asked the most when telling people about my dilemma is, “Why are you even bothering with a piston system? My direct impingement gun cycles supersonics and subsonics just fine, even without a suppressor *rabble rabble rabble*.” My answer is always: Why not? I have been tainted by the luxury of piston driven ARs, and I will not let my borderline-unrealistic dreams be coaxed astray by your ‘facts’. Here are some of my own ‘facts’:

- Piston ARs are much simpler to clean. Anyone who has shot a direct impingement AR-15 knows how caked the bolt and carrier components can get caked with carbon fouling, and cleaning off said fouling is a time consuming task all in itself (which cuts into my precious youtube cat video time). Ever since I switched to a piston driven AR, I’ve not had to scrub, scrape, or soak any part of my AR. Cleaning with a piston takes roughly 10 minutes, TOPS (just the barrel and a little wipe down in the upper).

- There is MUCH less gas in the face when shooting suppressed.

- I’ve been to the future; everyone uses pistons… And Apple comes out with the iCar. It drives itself and has room for four people and over 100,000 songs. I think it has issues though: it gets bogged down with apps and it won’t let you delete the songs you don’t want to hear anymore.

So, in my journey to establish a piston driven .300 Blackout Pistol that cycles reliably, I’ve discovered four very specific and sensitive variables that impact the success of these little nubblet firearms: The barrel, the piston system and bolt carrier, the recoil buffer spring, and the load recipe. Here is the setup I’ve chosen to run:

- Barrel: McGowen 9” Stainless steel pistol length gas system barrel (.300 Blackout, of course) with a 1 in 8” rate of twist.

- Piston System: Adams Arms XLP Pistol length kit with low mass bolt carrier (important)

- Recoil Buffer Spring: Standard (cut)

- Load Recipe: 220gr-230gr projectile, 11.0gr-11.2gr Accurate 1680

The Barrel

The first and most important thing to know about running a .300 Blackout with a piston system is that it should never have a barrel longer than 16 inches and should always have a pistol length gas system (regardless of barrel length); it’s going to need as much gas as it can get. Second, the gas port size will impact functionality and reliability. Many .300 blackout barrels will come with a gas port diameter of .075”-.090”. If you are running a 12”-16” barrel, that diameter range will work just fine. If you are running under 12”, you might find the gun running quite under gassed. I found that for short barrels, a piston system will need a gas port of .10”-.12”. That might seem large, but again, if you want reliability with subsonic ammunition, it will be necessary to let in as much gas as safely possible. The McGowen came stock with a .090″ gas port, and it had issues. So, I drilled it out to about .11” and it is now cycling everything just fine with the regulator on full-blast. If you are worried about overgassing, don’t be. The Adams Arms XLP gas block can be regulated with five different settings, so if it winds up over gassed, you can always turn it down.

The Piston System

There are many AR-15 piston systems on the market today, but I chose to go with the Adams Arms XLP kit. Why? Because it was the only one I could find in a Pistol length setup that had more than just three general regulator settings (and like my gas to be custom, dawg). Now, there is one problem with the XLP kit direct from the factory: The piston return spring is much too strong to reliably cycle our little subsonic nibblers. After a brief bout of GoogleFu, I found an alternate, lighter weight spring that can be obtained at ACE hardware; item number 540425 (you’re welcome).

As of 12/28/2015, a commenter named Bert Payne informed me that there is a better option. He states that the Adams Arms Stock spring is .038″ wire, .306″ outer diameter, 1.5″ length, with spring weights of 2.7lbs installed and 8.8lbs compressed. A Hillman “General Purpose” spring (ACE item number 540371) would be the best option, with a wire diameter of .032″, an outer diameter of .281″, and spring weights of less than 1.15lbs installed and 3.2lbs compressed. Best of all, it’s slightly shorter than the 540425 spring and doesn’t need to be cut. Thanks Bert!

The low mass bolt carrier that comes as an option with the Adams Arms kit is pretty damn excellent. It looks quite dapper with its undulated cuts, and the lower mass seems to help with cycling. Whether or not the lower mass has a gigantic impact on functionality is up for speculation. Regardless, it’s a good option, but it will increase the price of the XLP kit by quite a bit.

The Recoil Buffer Spring

Now, this portion may cause a little uproar on the interwebs. I utilized a standard weight recoil buffer and spring, but I cut the recoil buffer spring down to about 9.5″ to lower its overall spring weight. There is still plenty of weight in the spring, but it is considerably lighter. This actually made a HUGE difference in cycling subsonics. You can probably accomplish this if you buy a lighter weight buffer spring, but who actually buys anything in this day and age?

The Recipe

This is going to be the keystone of the entire setup. You can have a .300 blackout that can cycle factory supersonic ammunition, but if it’s not quiet, what’s the point of having it? Well, companies such as Remington, Nosler, HPR, and Sig Sauer have factory loaded subsonic .300 Blackout ammunition available, but not one of those manufacturers loads have successfully cycled my piston gun. One could extrapolate that the factory subsonics are designed for direct impingement guns sporting 16″ barrels (and I don’t humor any of that garbage). Thus, I decided to control my own destiny and chose to roll my own custom-tailored ammunition to accommodate my particular needs.

After months of trying out several different bullet and powder combinations, I’ve concluded that the ideal load for my gun is a 220gr to 230gr projectile sitting atop 11.2gr of magic pixie dust: Accurate 1680. According to Hornady’s load manual, 11.0gr of Accurate 1680 behind a 220gr projectile will produce a little under 1100 fps out of a 16” barrel. Since Wikipedia told me that 1125 fps is the speed of sound at sea level, in dry air, with an ambient temperature of 70° F (and since it’s on the internet, it has to be true), I chose this as my starting load with the belief that my shorter barrel would equate to lower velocities.

My initial tests began with some beautifully powder-coated 230gr cast boolits made by a buddy of mine who is into the casting scene. Without a sound suppressor, this load was definitely subsonic. They had a fairly mild pop and produced no supersonic crack down range; albeit, they did not cycle the action. Once I put the sound suppressor on, the round fully cycled the action (HURRAY!), but it definitely produced a supersonic crack down range (NO ME GUSTA). How could there be such a change in velocity change between unsuppressed and suppressed? Well, Mr. Chronograph tells me that these rounds are pushing about 1085 fps on average WITH a suppressor, so why are they producing a crack? It turns out that has to do with some fairly interesting factors in aerodynamics.

(WARNING: I AM NOT A SCIENTIST OR PHYSICIST – AFTER FURTHER RESEARCH, ALL OF THE FOLLOWING WAS PROVEN TO BE UTTER MALARKEY. IT HAS BEEN LEFT IN TO SHOW HOW HILARIOUSLY DUMB IT WAS)

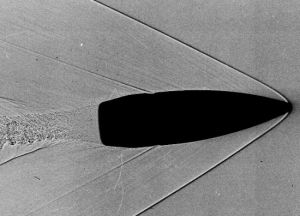

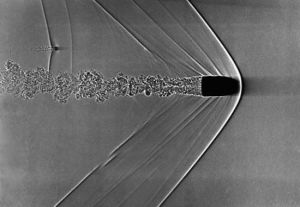

Me: Since the bullet is traveling near, but not quite at the speed of sound, it finds itself in a state of transonic flight. That is, the bullet might be traveling below the speed of sound, but the air travelling around the bullet (being pushed out of the way while the projectile moves through it) may be moving faster than the speed of sound; this will still produce a supersonic crack. So, my tiny brain logic dictates that if a projectile is very aerodynamic, the surrounding air will be able to get around the projectile at a lower velocity than a projectile that isn’t very aerodynamic. Allow me to use pictures shamelessly stolen from aerospaceweb.org to illustrate my ‘logic’:

|

|

As you can see in the pictures above, the more aerodynamic projectile (on the left) generates a much shallower angle in its bow shock during supersonic flight than the less aerodynamic projectile in supersonic flight (on the right). Because of that, I can conclude (in my completely unprofessional and uneducated opinion) that a shallower angle in bow shock = lower velocity of air traveling around the projectile…

UPDATE: 3/12/19

Except all of that that is completely wrong. The reality of this phenomenon is actually the complete opposite. The more ‘V’-like the bow shock (which is the physical manifestation of the sonic boom), the faster the projectile is moving. Most importantly, you can actually see that there are multiple lines coming off of the projectile. That’s because air moving over every little ridge and scratch is also breaking the sound barrier. I find that CRAZY, because it means that the projectile is creating a sonic boom not only at the nose of the projectile, but along multiple locations along the corpus of the projectile. NEAT.

You know, I can try to explain this, but a video by Smarter Every Day already exists that does a phenomenal job explaining this phenomenon. It’s starts at about 2:35 mark in the video. Ignore the in-video advertising this guy does… the rest of the video content is actually fascinating.

Back to the concept at hand, since every single little ridge and ledge on the projectile will cause the air moving over those ridges to make a miniature supersonic crack, the ideal projectile for this situation will be a heavy-for-caliber projectile with a long ogive and super slippery high G7 ballistic coefficient. I’d say a .308 diameter, 210gr VLD Hunter or 230gr Hybrid Target bullet from Berger would do nicely (I will be testing the 210gr bullets). Their price is a little steep, so after taking a small loan out and selling a kidney, I procured a box of 210gr Berger VLD Hunter bullets to test out this hypothesis.

I’ve tried a few different powders that many internet warriors have claimed will produce a cycling subsonic round in an AR-15 pistol, but only one powder takes the piston cake: Accurate 1680. It’s the slowest burning out of all of the powder choices suggested and it works beautifully in subsonic .300 Blackout. The load recipe I’ve found that works best is:

Bullet: 210 gr Berger VLD or Hybrid Target

Powder: Accurate 1680 11.0gr-11.2gr (this will cycle)

Primer: CCI 400 Small Rifle (really, any small rifle primer will work)

Case: Assorted converted .223 Brass (not 5.56 – don’t want to turn necks)

Deity: Christian Denomination God (to pray to so they work; truthfully, your choice of deity is important here)

The morning you decide to shoot, make sure you follow these steps exactly as laid out: First, wake up and look at your cell phone. Put cell phone down, get up, and eat breakfast in the shower (great way to save time!). Dry off, put clothes on WHILE brushing your teeth, deoderize, feed the cat, grab your range gear (not the cat), gun, and AMMUNITION (ammo is most important) and go to the range. Hopefully it will be a quiet day at the range so you can actually hear for supersonic cracks… and shoot at paper, not steel (everyone shoots subsonics at steel on youtube… don’t be a tool). Finally, you will hopefully get this to happen (sorry, I have no camera person and they were about to call a cease fire):

Conclusion on Berger Load: Chronograph clocked them at an average of 1080 fps, and although there was an echo down range, I don’t think it was a super sonic crack… It was hard to tell at the range, and just as difficult to discern from the video. I think the hypothesis needs further exploration… Regardless, the gun is cycling, bolt locks back on empty, and it’s fairly quiet. I’d say ‘Mission Accomplished’…? And just in case you come to an existential crisis in deciding to do this to your gun, just know that supersonic rounds still work just fine in this setup without any modification; just don’t shoot them through your form 1 MagLight suppressor (it’s a good way to turn it into a $290 projectile, though).

If you’ve had different experiences or have had success making a piston driven AR pistol in .300 Blackout work, please feel free to share your comments below. The more information we have out there, the less likely we’ll need to pay for a Sig Sauer MCX or PWS MK109 to get our .300 Blackout piston fix.

http://www.recoilweb.com/adams-arms-is-up-for-public-auction-149036.html

Any other choices for a piston upper now that Adam’s arms is gone?

LikeLike

NOOOOO!!!!!! THEY HAD SO MUCH GOING FOR THEM!

Aside from that, Superlative Arms might be another option. I’ve yet to try it with .300 Blackout, but it might work in a pistol setup. Their spring seems a tiny bit lighter than the Adams spring. Someone will need to test it and report back!

LikeLike

I have a piston .300 blackout pistol that I would sell if anyone is interested. It is top knotch/high end build. Adams arms piston kit, AA hand gaurd black, SLR rifle works upper and lower w/ green distressed cerakote, daniel defense black grip, Vseven lower parts kit, maxim defense rear knuckle w/ cheek weld (could buy and slide on a maxim brace), and 9″ barrel good quality cant rem name at the moment. Only less than 200 rds through it barely enough to test it out. It shoots super buttery smooth. Would sell for $2,500 firm.

LikeLike

Brownells will probably have 300 BLK out in this next:

https://www.thetruthaboutguns.com/2019/04/daniel-zimmerman/489975/

Might wait to see if this works. If they hold the price at $799, would be a bargain.

LikeLike

Neato torpedo! I’d be curious to see how this would fare in a shorty .300 Blackout.

LikeLike

I’m having issues locating that sping. Any help or links?

LikeLike

300 Blackout BRN-180 is coming very soon! Check Brownells , heck still hoping during Shot Show. Spoke to Marketing guy. They are getting lots of request for 300 Blk out.

LikeLike

THAT, and the Palmetto State Armory JAKL. If the JAKL turns out to be a reliable gun, I might just sell my precious unicorn piston upper and buy one of those… and that’s saying something, because I LOVE my piston .300 blackout upper.

LikeLike

How about something like this? https://www.brownells.com/rifle-parts/receiver-parts/receivers/upper-receivers/mk109-pro-complete-upper-receiver-9-75-black-sku100034986-129692-237873.aspx

LikeLike

YEP. Back when I wrote this, PWS was the only company making a piston .300 blackout. It looks like their prices have come down substantially from where they were five years ago. Anything under $700 is not bad. I’ve never used one before, so I’m not sure how well they work, but the MK109, in my opinion, is peak piston AR in .300 blackout.

LikeLike

I have the PWS 9 inch 300blk. Runs with and without can perfectly.. Thats a great price too.

LikeLike

That’s what I’m talking about! You run it suppressed as well! Is it gassy at all?

LikeLike

Yes, I use a Sig 762 QD suppressor. This rifle eats anything.. I have a PSA 300 blk also, had teething issues, loose gas block, but runs well too. The PWS runs smoother. And, its just nicer to clean too compared to the DI version 300 blk PSA 8.5 inch barrel..

LikeLike

That, my friend, is the epitome of luxury. Most people I know that have PWS uppers say the same thing. It’s smoother, cleaner, and overall a high quality piece. I might need to save my pennies to get one.

LikeLike

The brownells price is the same price PWS sells when its blemished or to Mil/LEO. Great price.

LikeLike

For Valentines Day it is another $55 off!

LikeLike

I couldn’t stand it. I had to get one today!

LikeLike

Big news everyone. Read page 97 -Brownells ad Recoil Magazine. Been waiting for this one. Oh, if you don’t have Recoil, It’s a BRN-180s in 300 Blackout. Includes the part no. 16 inch, 10.5 inch and 10 inch(why?). Think I’ll try to order the 10.5 inch. I’ve ordered the lower receiver (the authentic AR180 one) But bummer it is backordered.

LikeLike

Ok, here’s the deal. The ad has all 180 style uppers, the 10 Inch is the new 300 Blackout. I’m on the phone trying to order now

LikeLike

Quality articles or reviews is the key to invite the visitors to visit the site,that’s what this website is providing.

LikeLike

I am curious if anybody else has tried just building with a Superlative Arms pistol length piston conversion kit and enlarging the gas port, and what the chances are that if you enlarged the gas port to say…. .125 that there would be enough gas to cycle a standard BCG with a standard or maybe heavier buffer system?

The reason I ask because I talked SLR Rifleworks for a while one day… they have a little micro 5.5″ 300BLK barrel with a proprietary shorter-than-pistol gas length that runs a “jet” gas block (not adjustable, but they make an 80% and i think he said the other size was a 50% jet to to reduce gas level or run it wide open like they recommend with 300BLK ) — and he said with that jet block running wide open and their 5.5″ 300BLK barrel, you can run (and they RECOMMEND running) a standard weight BCG and standard weight buffers etc. They do NOT recommend low mass stuff with this barrel. He actually recommended if you were going to run the 5.5″ 300BLK barrel with a LANTAC E-BCG to use an H3 buffer, not an H2 (what they usually recommend) because the E-BCG’s bleed off less gas and cycle harder.

It just got me thinking…. well if they can do that and they have a proprietary (shorter than pistol length) gas tube with that barrel and they can run *standard* weight BCG’s and buffers with that and they cycle subs with a can and supers fine with gas wide open, then why couldn’t I just open the gas port on a standard pistol gas length barrel as needed, maybe up to as far as .125 and run a superlative piston conversion kit with that and use standard weight bcg and buffer? And use the bleed off of the gas block to cut gas flow back if any of that is needed?

I am new to 300BLK and learning but seems to me if I am understanding right that the farther away from chamber the gas port is the smaller it needs to be to get sufficient gas. So if SLR is getting enough gas through their port and wide open gas block that is *a shorter distance than standard pistol length to the gas port* sufficent to cycle standard weight BCG and buffer, shouldn’t it be possible to enlarge the gas port at standard pistol length location enough to run a pistol-length piston conversion kit and get enough gas to cycle standard BCG’s and buffers?

I am less excited about Adams piston conversion because of the much reduced handguard compatibility and requirement for low mass components. I’d rather build with an SLR handguard and superlative piston conversion kit, at least if that is possible? Seems like it could be.

Any thoughts?

Thanks

LikeLike

I’m running a Superlative piston system and I’ve gotten it nearly dialed in.

-12.5″ 300BLK barrel ~.130 gas port (bought 16in from Ballistic Advantage and had it cut to my desired length)

-Superlative piston conversion kit

-standard weight carbine buffer

-Tubbs lightweight AR15 buffer spring

I milled material off of the bolt carrier to a similar weight as the Adams Arms bolt carrier(I owned one briefly before finding it wasn’t compatible with my handguard), roughly 235g measured with my kitchen scale. Opened up the gas port to ~.130, running the piston kit without the piston spring. I initially tried it without clipping the buffer spring and with the gas block at wide open, no venting, but ran into inconsistencies with running the 220gr subs I purchased (every other shot wouldn’t cycle far enough to load the next round). Ran the supers flawlessly. Don’t have a can to test with yet. I’ve clipped off 2 coils of the buffer spring to an overall length of 10″, haven’t yet gotten a chance to test it again with the subs.

Hopefully this info helps in your endeavors

LikeLike

Excellent work! I’ve never been able to get mine to run subs without the can, so the fact that you get intermittent cycling means you are close. With the Tubbs spring, I’d be a little careful with trimming coils. It’s already pretty light, and you don’t want premature extraction, which could really mess up the timing with supers. You might need to start playing with handloads to get them to cycle consistently. For me, that was the only way to get them working in the beginning.

Keep up the good work!

LikeLike