I must admit, I’ve had two very prevalent fascinations over the past year or so: Sound suppressors and running a .300 Blackout AR-15 pistol with an aftermarket piston system. The first fascination compliments the second fascination, so the two marry especially well. However, the second fascination is the problematic player in the relationship. I can make (and have made) a piston driven AR-15 with an 8” .300 Blackout barrel cycle supersonic ammunition just fine, but anyone who knows anything about shooting .300 Blackout knows that the real magic happens when subsonic ammunition meets Mr. Sound Suppressor. The problem lies in lower pressure causing cyclic unreliability.

The question I get asked the most when telling people about my dilemma is, “Why are you even bothering with a piston system? My direct impingement gun cycles supersonics and subsonics just fine, even without a suppressor *rabble rabble rabble*.” My answer is always: Why not? I have been tainted by the luxury of piston driven ARs, and I will not let my borderline-unrealistic dreams be coaxed astray by your ‘facts’. Here are some of my own ‘facts’:

- Piston ARs are much simpler to clean. Anyone who has shot a direct impingement AR-15 knows how caked the bolt and carrier components can get caked with carbon fouling, and cleaning off said fouling is a time consuming task all in itself (which cuts into my precious youtube cat video time). Ever since I switched to a piston driven AR, I’ve not had to scrub, scrape, or soak any part of my AR. Cleaning with a piston takes roughly 10 minutes, TOPS (just the barrel and a little wipe down in the upper).

- There is MUCH less gas in the face when shooting suppressed.

- I’ve been to the future; everyone uses pistons… And Apple comes out with the iCar. It drives itself and has room for four people and over 100,000 songs. I think it has issues though: it gets bogged down with apps and it won’t let you delete the songs you don’t want to hear anymore.

So, in my journey to establish a piston driven .300 Blackout Pistol that cycles reliably, I’ve discovered four very specific and sensitive variables that impact the success of these little nubblet firearms: The barrel, the piston system and bolt carrier, the recoil buffer spring, and the load recipe. Here is the setup I’ve chosen to run:

- Barrel: McGowen 9” Stainless steel pistol length gas system barrel (.300 Blackout, of course) with a 1 in 8” rate of twist.

- Piston System: Adams Arms XLP Pistol length kit with low mass bolt carrier (important)

- Recoil Buffer Spring: Standard (cut)

- Load Recipe: 220gr-230gr projectile, 11.0gr-11.2gr Accurate 1680

The Barrel

The first and most important thing to know about running a .300 Blackout with a piston system is that it should never have a barrel longer than 16 inches and should always have a pistol length gas system (regardless of barrel length); it’s going to need as much gas as it can get. Second, the gas port size will impact functionality and reliability. Many .300 blackout barrels will come with a gas port diameter of .075”-.090”. If you are running a 12”-16” barrel, that diameter range will work just fine. If you are running under 12”, you might find the gun running quite under gassed. I found that for short barrels, a piston system will need a gas port of .10”-.12”. That might seem large, but again, if you want reliability with subsonic ammunition, it will be necessary to let in as much gas as safely possible. The McGowen came stock with a .090″ gas port, and it had issues. So, I drilled it out to about .11” and it is now cycling everything just fine with the regulator on full-blast. If you are worried about overgassing, don’t be. The Adams Arms XLP gas block can be regulated with five different settings, so if it winds up over gassed, you can always turn it down.

The Piston System

There are many AR-15 piston systems on the market today, but I chose to go with the Adams Arms XLP kit. Why? Because it was the only one I could find in a Pistol length setup that had more than just three general regulator settings (and like my gas to be custom, dawg). Now, there is one problem with the XLP kit direct from the factory: The piston return spring is much too strong to reliably cycle our little subsonic nibblers. After a brief bout of GoogleFu, I found an alternate, lighter weight spring that can be obtained at ACE hardware; item number 540425 (you’re welcome).

As of 12/28/2015, a commenter named Bert Payne informed me that there is a better option. He states that the Adams Arms Stock spring is .038″ wire, .306″ outer diameter, 1.5″ length, with spring weights of 2.7lbs installed and 8.8lbs compressed. A Hillman “General Purpose” spring (ACE item number 540371) would be the best option, with a wire diameter of .032″, an outer diameter of .281″, and spring weights of less than 1.15lbs installed and 3.2lbs compressed. Best of all, it’s slightly shorter than the 540425 spring and doesn’t need to be cut. Thanks Bert!

The low mass bolt carrier that comes as an option with the Adams Arms kit is pretty damn excellent. It looks quite dapper with its undulated cuts, and the lower mass seems to help with cycling. Whether or not the lower mass has a gigantic impact on functionality is up for speculation. Regardless, it’s a good option, but it will increase the price of the XLP kit by quite a bit.

The Recoil Buffer Spring

Now, this portion may cause a little uproar on the interwebs. I utilized a standard weight recoil buffer and spring, but I cut the recoil buffer spring down to about 9.5″ to lower its overall spring weight. There is still plenty of weight in the spring, but it is considerably lighter. This actually made a HUGE difference in cycling subsonics. You can probably accomplish this if you buy a lighter weight buffer spring, but who actually buys anything in this day and age?

The Recipe

This is going to be the keystone of the entire setup. You can have a .300 blackout that can cycle factory supersonic ammunition, but if it’s not quiet, what’s the point of having it? Well, companies such as Remington, Nosler, HPR, and Sig Sauer have factory loaded subsonic .300 Blackout ammunition available, but not one of those manufacturers loads have successfully cycled my piston gun. One could extrapolate that the factory subsonics are designed for direct impingement guns sporting 16″ barrels (and I don’t humor any of that garbage). Thus, I decided to control my own destiny and chose to roll my own custom-tailored ammunition to accommodate my particular needs.

After months of trying out several different bullet and powder combinations, I’ve concluded that the ideal load for my gun is a 220gr to 230gr projectile sitting atop 11.2gr of magic pixie dust: Accurate 1680. According to Hornady’s load manual, 11.0gr of Accurate 1680 behind a 220gr projectile will produce a little under 1100 fps out of a 16” barrel. Since Wikipedia told me that 1125 fps is the speed of sound at sea level, in dry air, with an ambient temperature of 70° F (and since it’s on the internet, it has to be true), I chose this as my starting load with the belief that my shorter barrel would equate to lower velocities.

My initial tests began with some beautifully powder-coated 230gr cast boolits made by a buddy of mine who is into the casting scene. Without a sound suppressor, this load was definitely subsonic. They had a fairly mild pop and produced no supersonic crack down range; albeit, they did not cycle the action. Once I put the sound suppressor on, the round fully cycled the action (HURRAY!), but it definitely produced a supersonic crack down range (NO ME GUSTA). How could there be such a change in velocity change between unsuppressed and suppressed? Well, Mr. Chronograph tells me that these rounds are pushing about 1085 fps on average WITH a suppressor, so why are they producing a crack? It turns out that has to do with some fairly interesting factors in aerodynamics.

(WARNING: I AM NOT A SCIENTIST OR PHYSICIST – AFTER FURTHER RESEARCH, ALL OF THE FOLLOWING WAS PROVEN TO BE UTTER MALARKEY. IT HAS BEEN LEFT IN TO SHOW HOW HILARIOUSLY DUMB IT WAS)

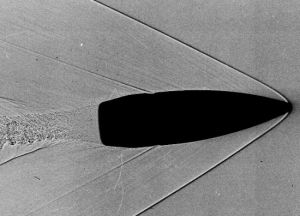

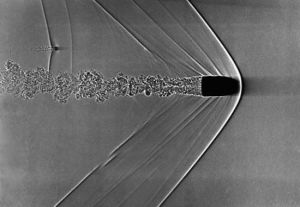

Me: Since the bullet is traveling near, but not quite at the speed of sound, it finds itself in a state of transonic flight. That is, the bullet might be traveling below the speed of sound, but the air travelling around the bullet (being pushed out of the way while the projectile moves through it) may be moving faster than the speed of sound; this will still produce a supersonic crack. So, my tiny brain logic dictates that if a projectile is very aerodynamic, the surrounding air will be able to get around the projectile at a lower velocity than a projectile that isn’t very aerodynamic. Allow me to use pictures shamelessly stolen from aerospaceweb.org to illustrate my ‘logic’:

|

|

As you can see in the pictures above, the more aerodynamic projectile (on the left) generates a much shallower angle in its bow shock during supersonic flight than the less aerodynamic projectile in supersonic flight (on the right). Because of that, I can conclude (in my completely unprofessional and uneducated opinion) that a shallower angle in bow shock = lower velocity of air traveling around the projectile…

UPDATE: 3/12/19

Except all of that that is completely wrong. The reality of this phenomenon is actually the complete opposite. The more ‘V’-like the bow shock (which is the physical manifestation of the sonic boom), the faster the projectile is moving. Most importantly, you can actually see that there are multiple lines coming off of the projectile. That’s because air moving over every little ridge and scratch is also breaking the sound barrier. I find that CRAZY, because it means that the projectile is creating a sonic boom not only at the nose of the projectile, but along multiple locations along the corpus of the projectile. NEAT.

You know, I can try to explain this, but a video by Smarter Every Day already exists that does a phenomenal job explaining this phenomenon. It’s starts at about 2:35 mark in the video. Ignore the in-video advertising this guy does… the rest of the video content is actually fascinating.

Back to the concept at hand, since every single little ridge and ledge on the projectile will cause the air moving over those ridges to make a miniature supersonic crack, the ideal projectile for this situation will be a heavy-for-caliber projectile with a long ogive and super slippery high G7 ballistic coefficient. I’d say a .308 diameter, 210gr VLD Hunter or 230gr Hybrid Target bullet from Berger would do nicely (I will be testing the 210gr bullets). Their price is a little steep, so after taking a small loan out and selling a kidney, I procured a box of 210gr Berger VLD Hunter bullets to test out this hypothesis.

I’ve tried a few different powders that many internet warriors have claimed will produce a cycling subsonic round in an AR-15 pistol, but only one powder takes the piston cake: Accurate 1680. It’s the slowest burning out of all of the powder choices suggested and it works beautifully in subsonic .300 Blackout. The load recipe I’ve found that works best is:

Bullet: 210 gr Berger VLD or Hybrid Target

Powder: Accurate 1680 11.0gr-11.2gr (this will cycle)

Primer: CCI 400 Small Rifle (really, any small rifle primer will work)

Case: Assorted converted .223 Brass (not 5.56 – don’t want to turn necks)

Deity: Christian Denomination God (to pray to so they work; truthfully, your choice of deity is important here)

The morning you decide to shoot, make sure you follow these steps exactly as laid out: First, wake up and look at your cell phone. Put cell phone down, get up, and eat breakfast in the shower (great way to save time!). Dry off, put clothes on WHILE brushing your teeth, deoderize, feed the cat, grab your range gear (not the cat), gun, and AMMUNITION (ammo is most important) and go to the range. Hopefully it will be a quiet day at the range so you can actually hear for supersonic cracks… and shoot at paper, not steel (everyone shoots subsonics at steel on youtube… don’t be a tool). Finally, you will hopefully get this to happen (sorry, I have no camera person and they were about to call a cease fire):

Conclusion on Berger Load: Chronograph clocked them at an average of 1080 fps, and although there was an echo down range, I don’t think it was a super sonic crack… It was hard to tell at the range, and just as difficult to discern from the video. I think the hypothesis needs further exploration… Regardless, the gun is cycling, bolt locks back on empty, and it’s fairly quiet. I’d say ‘Mission Accomplished’…? And just in case you come to an existential crisis in deciding to do this to your gun, just know that supersonic rounds still work just fine in this setup without any modification; just don’t shoot them through your form 1 MagLight suppressor (it’s a good way to turn it into a $290 projectile, though).

If you’ve had different experiences or have had success making a piston driven AR pistol in .300 Blackout work, please feel free to share your comments below. The more information we have out there, the less likely we’ll need to pay for a Sig Sauer MCX or PWS MK109 to get our .300 Blackout piston fix.

Nice article. There is just one issue. The real unicorn is the AA 1680 powder. Can’t find it anywhere and have been looking for months.

LikeLike

You are not kidding. I’ve been working off of a pound of AA1680 I purchased last year. I’m running dangerously low now…

LikeLike

Bert here – Subsonic bullets are not cheap (although Berry’s plated 220gn might be a game changer – for plinking). The most popular bullets for .308 are 155gn and 168gn, and quality bullets can be found for under 20c. The trick for light subsonics is to seat them low (like Vmax low). This keeps the powder from sloshing around, and keeps your SD in line. I’ve been using 155gn Amax and 168 Tipped Match Kings (XMas colors). Since they use half the powder, they come out to just 26c a round!

LikeLike

AA1680 in stock now here. https://reloadingunlimited.com/product/accurate-1680-1-lb/

LikeLike

Nice article. I went with a slightly different approach that led me to the same conclusion as you and ultimately to your article. I purchased an AA 9.5″ upper in 300 BO direct from AA before they discontinued them. Adams Arms knew they had a problem with these uppers but sold them anyway. My first experience with an Adams Arms upper has not been pleasant and certainly not worth the $1000 I paid for it. The upper would not cycle anything supersonic or subsonic. I ended up replacing the piston spring just as you did. It got me close to reliability on the subsonics with a suppressor. I have tried to find the spring you used #540425 and can find no such item at Ace Hardware so please post some additional info so we can find the same exact spring. They have a lot of springs but without knowing the length, diameter and poundage of the one you used, your info is not much help. The AA barrel gas port was .998 inches. I drilled it out to .125. I am using a buffer with all the weights removed and have cut my buffer spring multiple times. One of the biggest issues is that the AA XLP piston plug becomes frozen in place after firing a few shots and it will not adjust at all. You certainly cannot adjust it after putting a rail on the gun, because there is no way to reach the plug and apply enough force to make it turn. It takes a wrench and a lot of force to convince the gas plug to turn. I also had to replace my AA barrel because it was a 1 x 9.5 twist rate and the heavy 220 gr. subsonic bullets would tumble. If I had it to do over again, I would have purchased a PWS upper in 300 blk and been done with it. My rifle is still not 100% reliable and it will only cycle subs if there is a can mounted on it. Adams Arms sold me a pig in poke and it will be the last time they get my money.

LikeLike

Hi Stuart,

I’ll try to answer all of your questions as best I can.

1. I think I have a spare spring at home and I might still have the packaging. I’ll take some measurements and try to see if I can send you some additional information about it.

2. Are you hand loading or using factory ammo? I have had no luck with factory ammo, so I only load my own. In addition, my gun can’t run subsonic ammunition without a sound suppressor. I can run supers without the can just fine, but subs need a can.

3. “One of the biggest issues is that the AA XLP piston plug becomes frozen in place after firing a few shots and it will not adjust at all. “ THIS. VERY THIS. I have had the exact same experience with the XLP gas block. While trying to calibrate the gas timing, I had to do shoot without the rail so I could tune the gas block. This was actually a waste of time for me, because it worked best at the 100% gas setting. I left the gas on full blast and it has functioned 100% ever since.

4. Do you have the low mass bolt carrier? I have the low mass carrier and it might be the differentiating factor.

5. I agree with your choice to replace the barrel. 1 in 9.5″ is too slow to stabilize them 220gr pills. Mine is a 1 in 8″ and it works beautifully with supers and subs.

6. Are you running your gun with lots of lube? I run my gun super sloppy and it made the difference between cycling and not cycling. Also, I have a POF roller cam pin. You might want to consider getting one. It was one of the best investments I ever made. http://www.rainierarms.com/pof-223-roller-cam-pin

7. As for running reliably without a sound suppressor attached, I can’t run subs without my can either. I guess I justify this because I see no point in shooting subsonic ammunition unless I have a can on the gun. Just expect the gun to have cyclic issues when testing for stability without the can. My gun is able to run supers with or without the can just fine.

I wanted the PWS upper in 300 blackout also… It’s just so freaking expensive. Albeit, my upper didn’t start at $1000, so I can see your frustration.

LikeLike

Yes, I am rolling my own ammo. Factory ammo will almost always not cycle and ends up going supersonic. I am running the low mass carrier with lots of lube. (this was supposed to be included with the upper when I bought it, it took me a few months to realize they sent me the wrong carrier and that is why it would not cycle the supersonics). My new barrel is 1 in 8 twist. If I shoot supersonics, it is now over gassed and thus the reason I need to adjust the gas plug. My guess is that the plug is becoming very fouled after just a few rounds and results in not being able to adjust it. What is the point in having an adjustable gas block if it cannot be adjusted? Also, I had a typo above, my original gas port in the barrel was .098. Thanks for the tip on the roller cam pin. I will give that a try.

LikeLike

Stuart,

I couldn’t find the packaging for the spring, but I did find the AR15.com forum post where I got the idea. In the post you will find a picture of the spring and how short it was cut. I started working on my build about 3 months after this person did, so there is a chance they may not carry the spring anymore. He also mentioned that the reliability improved considerably once the piston spring was replaced.

https://www.ar15.com/archive/topic.html?b=3&f=126&t=640072

LikeLike

Hey, Curious how this gun was running? Also, have you ran any of the new factory 300BLK ammo on the market? I am getting ready to do the adams arms xlp kit on a 8.5 in pistol barrel, with a .099 barrel port. I may open it up.. But it runs subs fine in DI, right now..

LikeLike

Hi Steve,

The gun is still running great! I can conclude that all factory supers run fine (but that’s probably already a given), and both Sig Sauer subsonic and Nosler subsonic ammunition seem to work flawlessly with a sound suppressor. I still have issues running subs without a suppressor, but that’s jut the nature of my gun, it seems. There is at least one person who has reported perfect function with their piston gun running subs unsuppressed with a similar setup to mine, but using a JP silent buffer system, but I haven’t tried it yet.

LikeLike

The real question that I have here is …. with this work/cycle properly using off the shelf subsonic ammo like prograde, hornady or remington?

LikeLike

I haven’t tried since the gun has been broken in. I’ll see if I can find some and test it out.

LikeLike

Here is my build, running a 7.5″ barrel and Adams Arms XLP with Low Mass Nib Carrier and MVB Arc Stock – I did a lot of searching and had to replace all weights in the buffer with 1/2″ Delrin Rod since the stock has proprietary springs. Cycles perfect with supers unsupressed and perfect with subs suppressed by a Saker 762

BTW have tried a ton of subsonic and my favorite are the AE300BLKSUP2 rounds so far, gemtech cycle well too, very consistent, hope this helps! It’s been super reliable after reducing the mass behind the carrier without bolt bounce, if you can change your springs maybe try a Sprinco White Spring

Big thanks to Adams Arms again for their great customer service!

http://www.300blktalk.com/forum/viewtopic.php?t=94695

LikeLike

Well… Damn… So what was the weight in the buffer? Delrin is what (plastic)? What barrel and original/drilled gas port? Did you try to modify the springs at all? I was going to try flatwire springs.

LikeLike

There are several springs at ACE that fit the bill. They are Hillman “General Purpose” springs, with specs on their website. The 540425 has less coils once cut – not the best choice (binding). The 540416 is better (same number of coils cut as the AA spring). Best is the 540371 which is slightly shorter but doesn’t have to be cut at all. For tech nerds: The AA spring is .038 wire/.306 OD/1.5 len (2.7lbs installed/8.8lbs compressed). The Hillman/ACE springs above are .026, .028, .032 wire respectively, 9/32 OD. They reduce the power to less than 1.15lbs installed/3.2lbs compressed. GoogleFu..!!

LikeLike

You, sir, have added a substantial deal of information to the coffer. I’m going to add this information to the blog post with all credit to you.

LikeLike

My local Ace Hardware had places (bins) for some of the springs listed by others but never had them in stock. I lucked out and found a better assortment of springs at a local True Value hardware store. The spring I settled on was in a small clear bag with green and white labeling that said “Handi-Pack”, Part # 88247, 5/16 x 1 11/16, compression spring. UPC #738287882476. I did not cut or modify the spring.

This spring was less than $1 and has solved all my problems. I ended up having to go back to a heavy buffer to slow the speed down. My rifle now cycles everything I have put through it. It is even cycling some subsonic handloads without the suppressor. Suppressed, it has cycled everything I have put through it so far, approximately 1000 rounds of all different brands and handloads with perfect reliability.

So here is the final recipe that has worked for me:

*Adams Arms XLP pistol length piston block with the drive rod spring replaced with the spring above.

*Tubbs flat wire buffer tube spring with a few coils cut off (can’t remember how many)

*9.5 inch 1 in 7 twist barrel with the gas port drilled to .125

*POF Roller cam pin ( I was skeptical -but this made a huge difference and I have purchased them for every AR I own now)

*AA low mass bolt carrier

*Now run the bolt really wet with Superlube lubricant

*Replaced my buffer tube to one that has no rough machining inside (super smooth tube)

*Running superlube in the buffer tube with the Tubb’s spring

*Spikes ST-T2 buffer

*Cut a notch in my Samson EVO Rail that allows me to reach the XLP gas adjustment lever

*Running the AA XLP piston internals with Superlube (I can now move it after shooting)

*Cut the M4 feed ramps a little deeper and polished them (video on youtube shows how to do this)

The end result is that the bolt is running super smooth. Like it is on ball bearings. Now . . .If you offered to trade me even a PWS MK109, I would have to decline. Love it!

LikeLiked by 1 person

Interesting (love that POF but $$$)! I assume you are running subsonic rounds with a suppressor. What ammo? Have you been able to cycle the “notorious” Hornady 208 grain? Some reliability upgrades – the bolt catch is loose by default, when carrier drags over it, it leans back away from magazine follower – 300 Blackout ammo is heavy (10 rnds of 150gr/220gr makes mag 1-2 oz front heavy – full 30 rnd mag can be 11+ oz front heavy!) so it leans forward. The follower only has 1/16 inch contact with bolt catch so bolt lean back/mag lean forward… shims are available – this causes many of the bolt back/round feed intermittent issues.

LikeLike

I’m working through some of these issues myself. I’m reworking 300 BLK build with an AA XLP on a 8.2″ CMMG barrel. I went to the piston as the DI system I had ran really well, but it was absolutely filthy. After ~ 200 rounds, you needed a hammer to open the bolt (no exaggeration). Anyway, with subsonics, I’m very close to getting the bolt to lock open on last round and it will feed a new round occasionally. Really all I’ve done so far is open the gas port up to ~0.105. I’m hoping the light guide rod spring will get me there…..just have to find one. My big question is are you still able to run full velocity rounds without damaging the gun with the light weight springs? I’ve also looked at swapping the buffer spring to a JP rifle silent capture recoil spring as you can get them in a kit different spring weights. I’ve had great luck with them on other DI builds with suppressors and adjustable gas systems. Does anyone have any experience with them for these piston builds?

LikeLike

Mine runs supers just fine without any damage to the gun. The lighter weight piston spring will make a very large difference in functionality, so good luck on the hunt. I’ve never used the JP captured spring system, so I can’t give any advice there.

LikeLike

I want one!

LikeLiked by 1 person

Revelation! One of the great things about 300 Blackout is the scrutiny of every convention. Here is another (especial for AA pistons). Reverse the order of the buffer weights. Conventional thinking is that the heaviest weight should go toward the back (seemingly logical reasons). However putting the heaviest weight forward (at the bottom/closest to carrier/opposite bumper) changes some things. It initiates the inertial delay (the purpose of the buffer) immediately, rather than moving the carrier 1/8″ to stack the spacers and weights for affect. The AA piston’s challenge is that it is designed to exhaust excess gas – with the blackout we need ALL of the gas (this is why the AA needs 15-20% more gas than DI). If the piston moves 1/8″ (stopping to pull reluctant case) you shorten the stroke (only 1/2 in the first place), and open the cup. If the lugs turn, but the case still doesn’t come out you lose another 1/8″ stroke (the carrier stops again), and the cup opens more. Every time the carrier stops you have to overcome inertia again – up to three times! Immediate delay of the buffer keeps the piston cup closed, preserving gas, time for the case to shrink, before it begins to move. If you use a 3oz+ buffer, try a tungsten weight with aluminum weights (KAK sells individual buffer weights). Or go lighter with steel/aluminum/aluminum (2.2oz). (or at home depot – 1/2 steel nipple – .25 oz each or an even lighter spacer).

LikeLiked by 1 person

Sorry. The port size is 15-20% “wider”. The actual required gas increase (Adams Arms) is 40+%. Ex. from say .105 to .125 is a 15% wider gas port, but is actually 40% more gas (π × r2).

LikeLike

I tried to get my 300 blk to run an adams arms piston set up about 6 months ago, and had all but given up on getting it to run. After reading through all this I have some different weight springs to try in the front, I already have a JP Captive buffer will all weights and spring weights for tuning in the rear, Hopefully in the next month i’ll come back with good news.

LikeLike

Consider this… The AK-47 uses a piston (so many rifles do – in fact DI is in the minority). The starting gas port size is .125 in. (1/8″) – that is with a considerably larger case for more powder. For those nervous about opening the gas port, don’t be.

LikeLike

What upper is everyone using on their piston builds?

LikeLike

Thank you for posting this article, it was the first to come up when I was searching for “building .300 blk piston upper” so muchas gracias. I am seeking to build a .300 blk upper for my LWRC pdw. A piston system is required as is respect for the shortened buffer tube of the PDW. I presume that I can cross utilize the BCG from the LWRC upper (it already is set up for the shortened bugger tube and had the Delrin buffer at the rear of the BCG? This would be a first-time build for me, so I will be getting assistance from a friend who’s build a dozen or so DI guns and has the specialized tools. Any advice to the noob regarding this setup? Many thanks, J

LikeLike

Sounds like a fun project. Be aware that all companies have different dimensions for their bolt carrier (in relation to piston length and so forth). I would suggest getting a matching bolt carrier for the piston system you are using. As for the Delrin buffer, it’s not a bad idea, but it will most likely give way due to abuse when it impacts the back of the buffer tube. I’d say try to mill one out of Aluminum if you can with an indexing nipple to go into your bolt carrier (so it doesn’t lose center), then but a little rubber bumper on the rear portion (gotta protect yo’ shorty buffer tube). You may have to tinker with buffer spring weights, but it’s obtainable. Good luck on your build! Also, are you planning on using one of those H&K-style wire collapsible stocks? If so, avoid it at all costs. They are awful. They look cool, but are just plain awful to use.

LikeLike

Im really happy to have come across this post. I’m planning on building a gas piston 300 Blackout upper and this is the most comprehensive account of that process I have come across. DI is fine for some…. But like you, I’ve already been tainted by the luxury of a piston driven AR. No chance that I’ll be reverting back to DI for any reason. Thanks for the great post. If I have anything to contribute at any point, I’ll be sure to leave additional comments.

LikeLike

My two cents. Just wanted to thank you all for your insight. When I decided to build a piston 300 pistol I didnt realize id run into hick ups. I normally do my research before I start a build. That being said I wanted a pistol small enough and light enough to carry in my backpack. I have no intention of running subsonic or suppressed.I went with the AA piston with low mass carrier and Sampson rail. In order to shorten it enough to fit my backpack I installed a Law Tactical folding stock adapter. Upon test firing not a single round would extract. I tore it apart and checked gas block alignment and tried again…same thing. Then I found this page and started reading. The folding stock adapter added about two inches in length to the bolt carrier and of course more weight. I removed the weights from the buffer and again test fired. This time all rounds ejected.But it would not feed the next round. For $15 I installed a softer buffer spring. Now it runs flawlessly. https://www.facebook.com/photo.php?fbid=686014314870657&set=a.173219042816856.38390.100003862851666&type=3

LikeLike

It is truly amazing how much a buffer spring impacts the function of the gun. Glad to hear that it’s working now! As strange as it sounds, we who have piston operated pistol ARs in 300 Blackout are still a small group of people. Welcome to the group!

LikeLike

I too am really curious about the JP Silent Captured Spring idea. After visiting their website just recently, it looks like they’ve partnered up with Maxim Defence for a tube and stock project and it looks amazing! Especially for this type of application! I don’t have the tools or know how to do a project like this but hope to work with someone in the near future that could help accomplish this. I’m curious some of your guys’ thoughts and opinions on doing something that may be considered extreme: I’d like to cut my barrel down to 5″…I’ve seen a YouTube video of this posted by High Caliber Conversions LLC and it was cycling…but have not been able to find much more info on what kind of mods need to take place for that.

Love the article, love everyone’s input and excited to see updates

Thank you

LikeLike

The maxim defense stock does not work for this. The spring is a different wind than the rest of their springs. I tried both the 308 and 556 springs with it. And once you got it loose enough to cycle, it would not close the bolt. It’s a great stock otherwise.

LikeLike

What would drilling the gas port on the barrel make any difference if the hole on the gas block setting is smaller, that is what regulates the amount of gas, are you guys drilling that out too?

LikeLike

It might be hard to believe, but in the Adams Arms piston kits, the port size in the gas block is enormous… much bigger than the .11″ I drilled my barrel’s gas port out to. I keep my gas setting at 100% to ensure as much gas gets in that piston as possible. Drilling it out made a huge impact. You shouldn’t need to drill out the port in the gas block.

LikeLike

I will look tonight, what size drill, I see others going to .125″ or 1/4.

LikeLike

Rhoney, I know you mean 1/8″. Please don’t drill your gas port to 1/4″!

LikeLike

Crap, I was really hoping there was a way. I see they have different springs on their site, but I guess even using a slightly weaker spring results in cycling but not chambering, as you say…thank you for your input.

LikeLike

Question about gas pressures: I built a setup almost exactly like yours, 8″ barrel, YHM Suppressor, AA piston, .125″ gas port, light buffer spring, Ace hardware piston spring, load recipe, only diff I can see is the barrel brand. I’ve been working on this setup for 2 years & I still don’t come near cycling Subs… I’m thinking of trying a 10″ or 12″ barrel for more dwell time. But it doesn’t seem like the pressure would increase with a longer barrel because it would increase the velocity of the bullet, so I’d load less powder & obviously less pressure. Does this sound correct that a longer barrel would not help my issue?

LikeLike

You are 100% correct. A longer barrel = greater distance from gas port to end of muzzle = greater dwell time. I have a 9″ barrel, which does add dwell time, and that could be the difference between cycling and not cycling. HOWEVER, before I got my McGowen 9″ barrel, I had a 7.5″ barrel I bought from a place that doesn’t exist anymore, and I had no problems with cycling at all (other than it was so short that my suppressor pushed up against the release button on the piston system, which made me have to get a long thread adapter to use the suppressor).

I’m going to assume that you’ve already checked for gas port alignment, excessive friction on the op rod (like minute misalignment with the upper or contact with handguards), and full piston travel (sometimes the replacement piston spring can impede the travel of the piston. Verify that the shoulder on the op rod is making full contact with the bushing when all the way back. If the piston is short stroking, it will not cycle at all. I know all about this because I’ve had this happen). If so then troubleshoot with this list prior to losing hope on this barrel:

1. Friction can slow your gun down enough to prevent proper cycling. How lubed are you shooting your gun? I like to run my gun dry, but in the beginning, I had to run it SUUUUUPER sloppy with lube. I used Outers Gun Oil (the stuff in the pump bottle, not the aerosol) because it doesn’t evaporate and it is super slick. Also, take your buffer spring out and give it a healthy coat of grease. Molybdenum grease works great. Tetra Gun Grease also works, but I like the moly grease better. Not only will it make the gun cycle easier, it will make it much smoother and quieter. I also use a POF Roller Cam Pin, which cuts down friction considerably. I’ve never tried to shoot it with a regular cam pin, so I don’t know if it really makes a difference.

2. (silly question) Have you removed the gas rings from the bolt? The gas rings add quite a bit of friction and are obviously unnecessary in a piston gun. If you did remove them, then ignore this question.

3. Are you using the Adams Arms XLP kit with the low mass bolt carrier? I assume yes. If not, the weight of the bolt carrier might be slowing you down.

4. What weight buffer are you using? Try reducing/removing the weights from your buffer to further reduce the weight. Just know that if you remove the buffer weights, don’t try to bumpfire or shoot full auto. Those weights are designed to help mitigate carrier bounce, which really only applies to full auto/bumpfiring.

If all of those things fail, you might be doomed to buy a longer barrel. Sorry bro.

LikeLike

Just finished my build. Mimicked Stuart’s build but with an eight inch barrel. Cycles sub and super rounds. I’m setting up my tooling to roll my own ammo and have a question.

Are you putting a crimp on your case?

Thanks

LikeLike

Yes, I put a crimp on all of my .300 Blackout. Don’t want the bullet to set back during feeding.

LikeLike

Now, almost a year after your initial post… The SIG MCX 300 shortie is still a unicorn. I’m guessing that’s for a reason? LWRC, who ARE piston-driven, released their 300 blackout shortie – but in DI. Doh! LWRC went DI for their 300???? Man, that threw me off alight. That’s right about when I started to realize that maybe — for me — this was a bit like chasing a ghost. The MK 109 is known to be under-gassed, but is still the only instance that I can find (on the interwebs) of an actual factory-built, piston-driven 300 shortie that has a ‘good’ rep.

I too shared your vision. I actually referred to it as my ‘holy grail gun’; a piston-driven (for me, factory-built) 300 AAC shortie. And when the MCX 300 pistol was announced and touted and glamorized in numerous Shot Show videos, I got a little woody, thinking – could this be it? Well, I think the Big Guy might have taken a little offense to my holy grail reference… how many years later is it and the only reference I can find is one dude on a Sig Forum who managed to get an early release (before they shut it down) and had nothing but problems.

But, things aren’t all that bad, because right around that same time, I managed to score a limited edition AAC MPW 9 pistol… Yes, it’s DI. I’ve since embraced it. I’ve accepted that as my punishment for the whole ‘holy grail’ piston delusion I once had. The MPW is a gem though. Sure, it might be gassier than my Grandmother after a bowl of baked beans, but she shoots one damn ragged hole. I almost can’t believe how accurate this gun is with the right ammo. She cycles almost everything unsuppressed, all the way up to 208 gr AMAX at a measly 1050 fps (although just barely). Shoots the factory 220’s with no issue even unsuppressed, and loves 110 supers of course. 110’s without the can is really my preferred defensive loading/set up anyway (Barnes TacTX or Hornady VMAX). With the SDN-6 on, yeah… she’s gassy alright. But I just managed to score one of the new AXTS ‘Freedom Bones’ (what a cheesy name) and man, that thing makes a world of difference. Now most of the extra gas goes out the chamber. The only, only slight draw back is that it does get a little dirty, yeah. Not a piston. She shits where she eats. I get it. I have to clean her up after a trip to the range, but it’s really not all that bad. And in trade off, I get the supreme accuracy, simplicity and reliability of a DI gun. The MPW itself is all top shelf, KAC rail, Geissele trigger, a nibx MPI/HPT BCG, low-pro pinned block on a friggin cherry barrel with a 1:8 twist and an AAC FH (which I now keep the new AAC Blast Out over when not suppressed, to keep what little blast there is all down range).

As you can tell, my path was quite different, my equation quite different – as I don’t reload (don’t have the place yet), and I do not yet have the wear-with-all (gunsmithing skills, bench, etc) to really build my own as you have. So for me, it was really OEM or try to do something that’s outside of my practical experience and skill set. I saw the AA’s when they first came out and almost jumped on it, until I saw that you can’t adjust the gas setting without taking the damn rail off. That pissed me off to no avail. As soon as I ‘gave up the ghost’ of a piston-driven 300 AAC (Factory built) shortie, it all came together for me and it’s been a blast ever since. Until I can get a place with a bench and start learning the art of reloading, my quest now is to find the best cheap reman range ammo and have been experimenting with all of the big names, and some local shops too. In the meantime, every once in a while I’ll scan the interwebs for traces of the MCX 300 shortie and get a little laugh that it is still a fictional item. Glad I didn’t wait around for it. Maybe some day that will change. Maybe some day I’ll get a bench and some actual skills to do a build from scratch myself. Until then, it’s all MPW for me, and loving every minute of it (until of course I have to pay for more ammo – ouch!) :)

This article was awesome by the way. Hugely informative. Thanks.

LikeLike

Hey. Great article and great comments.

Just a heads up- when you cut a spring to make it shorter, you’re actually making the stiffness of the spring greater- it’s stiffer. When you install it, it has less preload, so maybe less initial force just sitting there- so it would (maybe) take less force to get it started moving- but for sure it’s stiffer. One of the things in the equation to calculate spring rate is the number of active coils in the spring. When you cut it, you are decreasing the number of active coils- increasing the spring rate… (Ping me if that doesn’t make sense.)

LikeLike

Yes, but by reducing the pre-load on the spring, the overall compression is reduced when the buffer reaches the back of the buffer tube. Don’t get me wrong; by cutting coils off, you are changing the properties of the spring substantially. We never made it to spring rates in my entry level physics class in college, so I’m not going to say I actually calculated the length to get it right. It just so happens that the amount I cut off works perfectly to keep proper function.

LikeLike

Lots of information here. My story in dealing with the AA piston 300 is quite similar to everyone else here. Thanks for the article. I’m happy to report that my 9″ AA upper functions 100% reliably. Mine is roughly a 2 MOA gun. Can anyone give me some feedback on accuracy?

LikeLike

I’m getting about 1.5 MOA out of mine. I’d like to believe it’s probably due to the fact that I am a poor shot. I don’t really use the gun for much else than up close shooting and potentially pig hunting down south, so I suppose that margin of accuracy suits my needs.

LikeLike

It’s upsetting when I have to strenuously focus on the fundamentals just to get a 2 MOA group. I’ve just accepted it as a short-range (less than 200 yards/meters) weapon system. Owning a blackout is going to get me into reloading. I can’t afford to buy factory ammunition all the time. I’m assuming reloads would be significantly more accurate.

LikeLike

I had a hard time finding 300blk factory loads for much less than a dollar a round, until my buddy (who used to work at Adams Arms) turned me on to sgammo.com

Excellent pricing, best I’ve seen anywhere. Has anyone tried the vltor A5 system to remedy cycling issues? I hear nothing but wonderful things about the A5 system. Any input would be greatly appreciated.

LikeLike

Anyone try superlative arms piston kit yet? I bought one because it would fit under my giessele rail. I started my build and am waiting on the piston to come in to complete it. I’m so great full for this page because it has amazing info on it. Thank you guys! I’ll post my experience once I get a few rounds down range

LikeLike

I would like to know this too. There’s not much information on the Superlative Arms / Syrac piston kits!

LikeLike

I actually know someone who knows the owner of superlative… I will pick his brain and get back to you guys. I also know that Adams Arms is working on a much improved XLP piston kit due in August that apparently works much better and has fewer moving parts and is actually adjustable by hand after firing more than three rounds. :) According to one of my good friends that works there, it’s supposedly the bees knees and will cycle just about anything…The second it comes out it’s going on my 7.5″ 300 black AR, so I will give you a full report after testing.

LikeLike

It runs supers unsuppressed with my jp silent capture with the lightest spring, won’t run subs unsuppressed, I did however purchase the nemo spring to so how that goes. I’m also getting ready to purchase a suppressor soon. I’ll keep you guys updated

LikeLike

Yeah!

LikeLike

The ammo is barely going supersonic with the can because the can increase velocity. That is why you are having the supersonic crack.

LikeLike

I’m “in the industry” and have talked with Tony Russo (the owner of Superlative Arms. (NEVER EVER MENTION SYRAC when you speak with them, it’s a very bad history) They are working on a dedicated 300 Blackout pistol length piston kit. That’s all I can say right now. This info is a week old. His current pistol kit apparently will not work although I’m trying to build one right now to make it work based on his suggestions. My biggest problem is that his current piston kit will not fit under a 2A Armament hand guard. I’ll have to do some machining to the hand guard to make it fit. It’s also advisable to get a JP Silent Captured buffer system and their spring kit.

I should have some more info shortly on my build. Based on some info from Tony I think I can get it running.

LikeLike

Whoa! This is interesting news. Keep us posted!

LikeLike

Hey, I like your red home made mag light suppressor! Care to share where you got the parts and how you assembled? Very interested, I know a company in Arizona I think was selling all the freeze plugs and mag light tube, SD Tactical I think, but I can’t find them anywhere anymore. Would love suggestions on alternative sources for the plugs and stuff as well as assembly suggestions?

Also, in your blog you mention the low profile BC with the Adams Piston is critical. Why is that? Adams is backordered on their low pro BC so you saying I shouldn’t order it without the low pro?

Thanks!

LikeLike

The Maglite tube is quite literally a Maglite flashlight body. I got it for Christmas in… 2007 from my mom, I think… Since I trust you are following the law, now that you have your tax stamp in hand, SD Tactical still sells end caps, and also now sells “Barrel shrouds” that look and function a lot like the tube I used for a 9mm Form 1 build. They are made of titanium and are pretty legit. The freeze plugs are for a 2000 Chevy Malibu LS 6 Cylinder, and can be picked up at any auto parts store.

You can also get storage cups for D-Cell Tubes. They work great! JMPF is the place. I highly recommend the Stainless Steel cups for strength, but they are heavy. I’m not sure if they do it anymore, but you used to be able to buy a single Steel cup, and Aluminum for the rest for a much lighter can. Best to use the Steel cup as a primary baffle, because it needs all the strength to withstand substantial abuse.

As for the Adams Arms >>>Low-Mass<<< bolt carrier, you need a reduced weight bolt carrier to help with cycling. The subsonic .300 Blackout is super low pressure, so the lighter the bolt carrier, the easier it is for the gun to begin the cycle. I wouldn't want you to get a regular bolt carrier, have cyclic issues, then have to buy the low mass bolt carrier separate. Go low mass from the beginning and save yourself the trouble.

LikeLike

I’m starting to build a 300 blackout upper from the ground up, I’m glad I found this article! I’ve been looking for a lot of stuff covered here, and havn’t found much info. I also have the piston bug and don’t want to go back to DI. I was thinking of using the newer Adams Arms P-Series gas block, it looks like it’s easier to adjust and has 5 positions. I want to use a 12in Samson EVO hand-guard, but I may be rethinking that. I also wonder about a lower Mass Drive Rod. I have a AA CORE-15, and I think I remember they said they used a lower mass drive rod to reduce felt recoil, I don’t see any low mass drive rods for sale though.

I also checked out Superlative arms, and may look back at them when I buy a piston kit. I’m just starting the get parts so it may take another year. This is also the first upper I’m going to completely build on my own, so I may mess up many things.

http://www.adamsarms.net/pistol-length-piston-kit-micro-adjustable

Thanks!

LikeLike

I’ve personally never heard of a low mass drive rod. I’m not sure I’d want one, either… The drive rod needs to be stout to prevent bending or breaking, so I’d prefer whichever was stronger.

As for adjustment, You will only need to have the gas port on full blast for .300 blackout. I’ve got my barrel port drilled out to the largest diameter, and it’s just barely enough to cycle subs WITH as suppressor. It will cycle supers just fine with no overgassing issues.

Best of luck to you!

LikeLiked by 1 person

I own 2 of the new micro blocks from Adams arms…one is on a upper I built myself…7.5″ faxon barrel, 10.5″ Seekins MCSR hand guard. AA stripped upper. (Suppressor is tucked). The other is a 9.5″ upper that is all Adams arms. By the way, are you sure it wasn’t a low mass bolt carrier you were thinking of,? Never heard of a low mass drive rod from those guys. Anyway, the 9.5 with the new block will cycle 123gr and 150gr supers (full gas setting) where the older xlp block on the same upper would only cycle 123gr supers, so there’s something to be said for the new micro block other than just the ease of adjustment compared to the xlp. The 7.5″ upper only runs suppressed, and I can actually reliably cycle 200gr subs supppressed on the 2nd setting (one away from full gas) I highly recommend their new micro block. For the record, neither upper will cycle subs unsuppressed. Cycling subs reliably unsuppressed is a true unicorn…doesn’t exist.

LikeLiked by 1 person

Yeah I knew about the low mass carrier, I must have mis read somewhere about the low mass drive rod.

http://piston.adamsarms.net/adams-arms-cor-upper

LikeLike

Please Help! If I purchased the following items:

– Pistol Length Piston Kit – P Series Adjustable + Low Mass Carrier

– 10.5″ Faxon Barrel

– Remington UMC 120gr AAC BLK

– KAK Shockwave Blade

Will this build work?

LikeLike

It should work, yes. Please let us know.

LikeLike

As long as you are only planning to shoot supers, it might work ok. You might need to open the gas port (maybe), you might need to reduce the buffer spring weight, and if worst comes to worst, you might need to reduce your piston return spring weight. Regardless, start with what you have, and don’t put your handguards on until you have fully function checked everything. You will have no choice but to waste ammunition test firing. Good luck and godspeed. You will be soon among the few of us who run 300 blackout piston guns.

LikeLike

I was going to say the exact same thing as thisguy. You’ll likely have to drill out the gas port if it doesn’t cycle, and don’t plan on running subs unless you supress it. I don’t know anything that will reliably cycle subs unsuppressed with factory ammo. The older AA 300blackout gas ports were .125″, but with the new micro blocks they’re actually a little smaller. FYI, I didn’t have to drill out my 7.5″ Faxon port at all, so you should be ok.

LikeLike

Thanks for all the information. It is very helpful to know that there are people out there that will help. On another note, I just got an email back from customer support at Adams Arm and they also confirmed that it will work. With that said, they also mentioned they are in the process of releasing a piston conversion kit for the 300BLK. And the price tag on that is about $385. Is it worth waiting for that or just get the one that they are currently selling?

LikeLike

That’s a tough call. It’s fantastic news that Adams will be making a .300 Blackout piston, but since I’m not sure what the piston system will look or function like, I can’t weigh in on whether to wait or not. That price tag is sure steep… I wonder what changes they’ll bring to the table with this new piston kit.

LikeLike

The kit is now on the website. Low mass BCG and light piston spring. NIB options.

LikeLike

http://www.adamsarms.net/300blk-piston-kit-p-series-adjustable-micro-block

It looks like Adams Arms brought a kit back, currently it’s on backorder.

LikeLike

Thank you! This whole writeup, and all the comments, was instrumental in a) making me believe there was hope for this after trying and failing with the Superlative Arms kit, and b) showing me the way.

Two things I had to do are: drill out to a massive gas port size of 0.14, and modify my Midwest barrel nut to allow the piston to travel farther. That second part was crucial as the piston’s travel distance directly correlates to the amount of energy it can translate into the bolt carrier.

Now it’s happy as Larry, using a JP Enterprises heavy buffer, 7.5″ Faxon barrel, and a Saker.

I’m shooting home-made 220gr subs. Haven’t tried it with factory yet, but as that’s not a real scenario for me anyway, I’m happy where I am.

LikeLike

Read through this blog a couple times! Lots of info.

Thinking of doing a build.

Curious if any of you have tried or thought of trying the LMT enhanced bolt carrier group.

Seems to me this may salve the low pressure issue by increasing the bolt lock time and thereby giving more time of full pressure to work with? Seems like the added carrier mass problem would be negated by the extra cycle time?

Thoughts?

LikeLike

Well, in a direct impingement gun, the gas issue is almost non-existent. I’ve got friends with DI guns running the exact same barrel as I have, didn’t drill out the gas port, used standard buffer parts, slapped the gun together, and had 100% function from the get-go. However, I wanted a piston driven gun, so I couldn’t use a DI bolt carrier. The Adams low mass bolt carrier works great and comes with the kit, so it’s the route I went.

Now, addressing your theory: Adding locking time to the gun would not help with the cyclic issues. The problem with using a piston system in a short barrel is that if the gas port isn’t optimized to accommodate for the added mass of the piston operating rod and return spring, the bullet leaves the barrel well before optimal pressure is established to cycle the action (the dwell time is too short). The idea is to achieve optimal pressure prior to the bullet leaving the barrel. The only way to address this is to increase the dwell time (by using a longer barrel) or open up the gas port to allow for greater gas volume to enter the piston chamber, counteracting the lack of dwell time. By using a low mass bolt carrier, you further mitigate the added weight of the piston operating rod and return spring by removing weight from the carrier. It reduces the overall mass of the moving parts, thus reduces resistance during cycle.

So, if you increase the locking time, it will only increase the need for more dwell time.

LikeLike

I too am trying to build a piston driven 300 blackout “pistol”. I am sold on the piston system after buying an LWRC IC enhanced. It is my most awesome 5.56 and will never go back. I even recently traded a NIB SMOS cause they suck for some random fire arm just to not have it. Keeping my daniels defense and JP DI guns just cause I can’t get my money back. Going to beat the hell out of em though. And I plan to buy another LWRC piston gun in the near future just because!

So here’s with the piston 300. I have so far…a barrel. BSF 10.5″ carbon fiber. I have an SLR receiver set on it’s way. And an SLR handguard that I don’t know if it will work for the size of the operating system. Superlative arms said that they have an SLR handguard rifle that works with their piston system so I am just hoping that the SLR will work with the Adams arms piston kit. Do have the adams arms low mass kit on order. Seems like I might have it next year. {Adams, you guys suck at answering the phone and you must not have email. I hope your parts are worth the wait!} So yes, I am waiting on my piston kit and hope it comes some day before Dday. Problems arise here—

**I have asked BSF what the gas port size is after reading this article and will figure that out soon. If i need to drill could you tell me what size drill bit to use in english?

**My plan was to use a JP silent capture spring in my maxim defense buttstock. I have two springs, one an H2 on an H1. I’m really hoping this is not a problem. What do you think?

**As for ammo, well I really do not plan to make my own. Was planning on the beck 208 gr amax.

http://beckammunition.com/ammunition/300-blackout/300-blackout-208gr-a-max-subsonic.html

What do you think???

**Also adams arms web site mentions that I can use a daniels defense omega rail without problems and plan to use with one of my builds. But hoping that my SLR helix works. I am really not sure why one would work and not the other.

Any help would be greatly appreciated. Also I would be willing to add to this post in a couple of months after I get the gun built and some lead down range to let you all know what the results were.

LikeLike

Also, I just heard back from BSF barrels concerning their gas port size. It’s only been 5 min. since i asked them which is a testimony to their excellent customer service. They even answered a question I had for them at 9pm last night….

The port size on their 300 blackout 10.5″ barrel they said was 1.13

LikeLike

That might work out just fine! Stick with it, and if it doesn’t work, you can always go max at .125″

LikeLike

I drilled my gas port out with a 1/8″ drill bit. Make sure you use a dowel in the barrel or something to prevent over travel when you drill it out.

I’ve never used a JP silent buffer system, but I think other people might be using it with pistons. It will need to be light, but not too light or the extractor won’t get over the case rim. I’m pretty sure the JP is well calibrated enough to function, though. What will make a big difference also is a lightweight piston return spring. I’m not sure if Ace Hardware still sells the spring I talked about in the article, so you might have to dig around to find one.

As for the handguard, I’m not sure it will work, but that’s because I’ve never used one. The barrel nut is the real concern, as the Adams kits require a barrel nut for the piston return spring and bushing to push against, and the dimensions need to be pretty close to a standard barrel nut to function (or will require modification). The Superlative kits don’t require a standard barrel nut because their return spring is within the gas block, so obviously they don’t have that limitation.

Best of luck to you! Piston .300 Blackouts are damn excellent. Keep up the fight!

LikeLike

Thisguy—

https://www.primaryweapons.com/mk109-mod-2-m-upper-300-blk

Have you heard of PWS. I have spent countless hours in the last 3 months scouring the web for the unicorn. So far closest I have come is Adams arms piston kit and PWS upper. I am going to call PWS tomorrow and ask them about their system. I was planning to use an adams kit with a daniels omega rail and a BSF barrel like i mentioned, but if PWS has a complete rifle that has no issues I would prefer to go that route. Mostly don’t like the spring on the adams kit. Have you ever used or seen the piston system on an LWRC? Their system is like 1,000 times more rugged than the adams kit. So its hard to want to get something like that. Superlatives return spring is same as mag release spring and it goes in the gasblock. Super cheesy. We’ll see what PWS says tomorrow. Just wondering if you’ve experienced them?

LikeLike

I would love a Primary Weapon Systems MK109 in .300 Blackout. A long stroke piston is SEXY AF. They are just ungodly expensive, and I’m too poor for that right now. If you can get one, do it! I’m not sure how they handle subs and heavies. Their website says that it might cause issues without a suppressor, but if you have a suppressor, then it may not be an issue.

My very first lustful piston love was the LWRC M6A2-SPR (the old one that was self regulating – the spiral fluted one prior to the IC models), but as much as I love them, they do not have a piston model in .300 Blackout. From what I’ve been able to find, all of their .300 Blackouts are Direct Impingement guns, and I’ll have none of that.

If superlative says that their return spring is the same as the mag release spring, that’s rather funny. Albeit, if it works, there is nothing wrong with Superlative’s design… But I have no experience with it on a .300 blackout. I would love to test one, but I’m pretty happy with my setup right now.

LikeLike

Just wanted to post a successful build for 300blk with the Adams piston kit. Everything has functioned perfectly so far, although I’ve only fired less than 30 rds. Supers and suppressed subs have cycled and bolt has held open on the last round.

10.5″ ballistic advantage barrel pistol length gas port

Adams Arms newest 300blk adjustable piston kit with low mass carrier

Aero precision upper/lower and aero enhanced gen 2 handguard

(Note the enhanced aero upper won’t work without serious mods, if at all, due to its integral barrel nut configuration. I had the non-enhanced version but still had to mill out a slot for the bushing to sit in the barrel nut at mil spec length (0.85″) distance from the upper.)

Hiperfire 24 3 gun trigger

KAK shockwave pistol brace kit (2.9 oz buffer weight, standard spring)

Jp enhanced bolt and POF roller pin

No mods other than milling out the barrel nut to get it to work with the drive rod bushing. Gas port was 0.092″, did not drill out. The suppressed subsonic brass ejects at about 3:30-4:00, so getting close to being undergassed. Factory 220 gr sig sauer ammo and Remington ammo was used. Supers were AE 150 grain. Suppressor for the subs was a Rugged Obsidian 45. Adjustable gas block was left wide open.

Moral of the story is to make sure to try everything as-is before assuming malfunctions will occur. You might get lucky. I almost drilled out the gas port during the build before deciding to try it out first.

Next two items will be trying the JP captured spring with alternate spring pack (going with standard not H2 version since even the standard version is heavier than the listed 2.9 oz buffer weight with the functioning KAK kit); and then replacing the KAK pistol blade kit with a collapsible carbine stock once my SBR paperwork clears.

Everything you read from JP says you need the heaviest SCS kit available because the chart says SBR/piston/suppressed/6.5 or larger caliber…each contributes to needing the H2….but I just can’t see putting in a super heavy buffer weight with a low mass BCG. They’re probably right but then Adams must be wrong to require the low mass carrier. I don’t know but it works light so I’m sticking with it.

LikeLiked by 1 person

YEAH!!! Great to hear about another successful piston gun! Does the return spring on the new Adams 300BLK piston kit feel fairly light, or does it take a considerable amount of force to compress it? The standard weight spring takes quite a bit of force to compress compared to the one I had to find. I know they’ve had lightweight return springs in the past, but I’ve never actually seen them available on the Adams website.

Also, YES, thank you for the insight on the gas port. Everyone will experience different results, so everyone should test before drilling.

JP might be referring to running high pressure calibers when they recommend the heaviest stuff in SBRs, pistons, and suppressed stuff. 300BLK is obviously lower pressure, so their recommendation may not necessarily apply. If it works for you, however, don’t change a thing! The most important part is that your gun is purring like a sewing machine… or running like a kitten… or however that saying goes.

Welcome to the Brethren of Quiet Piston Driven .300 Blackout Pistol/SBR Owners!… or the… BQPD3BPSOs?

LikeLike

I’m not sure on the return spring weight. Nothing to compare it to. It’s pretty stout, but not too heavy. If I can figure out a way to hook up a trigger gauge without taking it all apart I’ll try measuring it next time. When I was at Ace I looked for the springs you mention in the article. Found them, but the parts bins I wanted had a jumble of different springs in them so I have no idea which was correct. All the other 100 or so spring bins were perfectly sorted…some gremlin must have read this article and decided to screw with me.

Do you happen to know if all the Adams kits have a little spring you need to install at the back of the bolt when you install it in the carrier? It kind of surprised me since the Superlative piston kit I have for a carbine 5.56 doesn’t have that spring and it functions perfectly without it. BTW, Superlative specifically states their system will not work for 300 BLK, or I would’ve gotten one. No issues with needing a mil spec length barrel nut for the return spring bushing, the spring is not exposed to the elements, plus you can get standard mag button springs for $1 as replacements at any decent gun shop if that spring does wear out. And you can pull the drive rod and spring out the front of the gas block for cleaning very easily. You need to remove the whole gas block to do the same with the Adams kit. I’ve read that Superlative is working on a 300 BLK kit for release “soon” for maybe 6-8 months now. Not sure it will ever come out and I didn’t want to wait anymore.

I guess the reasoning from JP on the heavy buffer (according to what I could glean from various forums) is that (1) the heavier weight keeps the case in the chamber a bit longer which lets the case expand and shrink down before the extractor tries to yank it out (less wasted energy), and (2) the extra bit of time allows more gas to go down the barrel rather than back through the chamber, providing more “working” gas to cycle the action and push the bcg back further. That’s what I understand although I can’t find it stated exactly that way. And of course that discussion is for DI guns, but same principles should apply to piston guns. To make it more confusing, you’ll find people that are getting their 8″ barrel DI guns to work with three tungsten weights and the second to heaviest spring on the SCS and it functions great, and others that use the standard light SCS with 3 steel weights and the lightest/white spring and that works. Go figure. I guess if the heavy scenario people are right then the one benefit is their brass should last longer. But lighter will cycle faster with less recoil because of less reciprocating mass (maybe?).

I should be able to try out a standard SCS with my setup next weekend, and got the spring pack in case I need to try a lighter spring. I’ll post my results once that happens. If it won’t work at all then I’ll gladly put the SCS in a different AR.

LikeLike

Suuuuper interesting!

Yes, the Adams kit comes with a bolt spring. I’m not sure it’s 100% necessary, but it probably helps (…probably). The Osprey Defense OPS-416 I’ve used in the past didn’t have the bolt spring either and it functioned just fine. I think Adams might have pioneered that… but I might be wrong. It might just make it easier to get the bolt carrier back into the upper when you take it out. When it warbles around and cams out of place, it’s a bit of a pain in the ass to get it to hold still sometimes.

LikeLike

Adams arms does have the small bolt spring. Just got mine in yesterday. Though the size of the gas block is not right and i will have to send back. Would have been nice if they listed the size. Not sure if im stuck on the build with my .875 size barrel.

But i got a pws 9″ 300 blackout ordered yesterday. They said they have been sucessful with their 300 blackout to cycle subs and supers.

LikeLike

Ooof, that’s rough. Barrels measuring 0.875″ at the port diameters are truly the ‘tweener children, and get little love. I’m not sure who is even making a piston block for that size of barrel… You might be stuck… or will have to build a … a… DI… Gun… Eww..

LikeLike

Just a quick update. Tried the standard JP silent captured spring with the steel weights and std spring and everything still worked great. Brass ejected about 3:30, bcg held open on an empty mag with subsonics (both suppressed and unsuppressed). And the rifle shot a little quieter without the buffer spring noise. The JP SCS didn’t have a dramatic difference though, in this particular rifle, and I will probably put it in a different AR with much more annoying spring noise.

LikeLiked by 1 person

If you are getting full function shooting subs without a suppressor, that’s an exceptional improvement!

LikeLike

Good news…. My hand guard was a 9.7″ and the barrel with the .875 size at gas port was said to be a 10.5 but did not fit with the hand guard. Turns out the manufacturer does not measure their barrels to industry standard. So I get to send it back and will be buying a Faxon 10.5″ barrel and an adams arms kit. I’m glad cause this gun is so nice I didn’t want to do it as a DI gun. Check out SLR. Most would be familiar with the hand guards. But they make a receiver set with the most detail I have seen yet on the market!

The unobtainable unicorn is now becoming a stallion. So someone can build their own with an adams arms kit… and then to get a manufacturer texted prebuilt there is now 2 options that I have found for a SBR or pistol 300 blackout piston gun… PWS who makes a very nice gun and Sig is now making a piston 300 blackout pistol. Sig’s looks really nice. Have not shot it though. But my PWS is sweet. I started this build before i found PWS or i might not have done it.

LikeLike

I know you’ve had this post up for almost three years now, but it’s still an excellent read and the amount of thought you put into your build is inspiring (and quite helpful). I would love to hear what your opinions are on some of the newcomers on the market (as well as my small predicament). I am dead set on either buying or building a piston driven 300 blackout pistol for primarily suppressed shooting. The 9″ MCX Virtus is a top contender right now especially since it’s buffer-less, but I’m a little hesitant due to the newness of the system. On the other hand, I like that the Adams Arms piston kits have a tremendous level of settings (100%-11% for the new P series). I know that the Virtus has an adjustable gas block as well, but, the fact that I could build a traditional semi-auto gun that has the capability to make single, quieter shots is tantalizing. I live on about 11 acres of property, but I do have some neighbors and I try to keep the noise down as much as possible. Any parting thoughts on the build vs. buy question given all the recent developments and your long term experience with your set up?

LikeLike

The MCX is a hell of a weapon. If I had the money, I’d probably own one, but since I don’t… well, I don’t. From what I have read, the Virtus should be able to cycle subs suppressed just fine, so that shouldn’t be an issue at all. I’ve been told it can run subs unsuppressed also, but I have no verification on that either. I’d do the MCX over the Adams build if I had the choice. The reason being that I’ve had to make a LOT of modifications to make my gun work with both subs and supers, where the MCX is designed to function properly from the get-go. If you can do the MCX, do it! You won’t be disappointed.

LikeLike

Don’t forget to check out PWS. I have their 300piston gun and it is awesome! Very rock solid. I’m going to look up the MCX now…

LikeLike

Thank you for the honest reply. A good part of why I was attracted to 300 blackout had to do with your build and the journey of creating something truly unique. I concede that a fully functional weapon which requires no modifications whatsoever is the most satisfying in the immediate sense – and it’s refreshing to see someone who put that amount of time and energy into their work say as much. I have the funds for the Virtus, but I’m still a little torn. My dream piston build (with silly features like a side-charging upper) is still quite a bit less than the MCX pistol even with a military discount. Plus it doesn’t help that I keep reading the comments and seeing degrees of success with similar DIY setups. Damn my indecisiveness…

LikeLike

I have an Adams Arms 300blk with. 7.5″ faxon barrell with the new micro gas block and have had 0 issues…flawless…both suppressed and unsuppressed supers, and suppressed subs (haven’t tried unsuppressed subs but I should) and paid a ton less than a virtus. Just saying, the new AA stuff is extremely reliable.

LikeLiked by 1 person

Faxon barrels are not expensive…but sure are nice. I bought a Faxon 10.5″ gunner profile .300 barrel for the SLR rifleworks build that I am doing mentioned above that I’m waiting on the adams arms piston kit for. I can’t wait. Good to hear about the adams arms. I will update when I get my suppressor and let all know how both guns do. Gorilla Ammo has some sweet deals on one time reman ammo and it’s really nice. They have both subs and supers for .300.

LikeLike

Thank you for the input! I’m actually leaning towards the build option and I’m glad to hear yours is working so well. I’ve been pricing out my dream set-up and I found that even with a military discount, the Virtus is still a good $600 more expensive. I could put that extra $600 into ammo/reloading/tax stamps and still probably come out ahead. If you don’t mind me asking, what suppressor are you running on your Faxon?

LikeLike

Silencerco Omega.

LikeLike

Well I found this article and I must say it has been pivotal in my 300blk sbr. I was undergassed the return spring can still be found at ace 3 years later, and now it seems there are factory subs that will cycle a piston gun. I almost bought a Barrett .300 pistol but now I’m glad I saved about 1000$ for a suppressor. I messed up and bought the jp scs with H2 buffers so I have 30$ worth of tungsten that is worthless to me. 1/8″ gas port is a must and I found in my barrel I actually had to drill off center of the factory hole in order to get the clearance needed for the piston rod.

I ran into one issue with my low mass carrier that caused me to have to get a warranty replacement from AA but there customer service was excellent and in less than a week I now have a functional piston driven.300 blkout sbr with silencerco muffler. Now just to get my ATN thermal scope and the hogs will be in serious trouble!

LikeLike

Glad to hear it! I hope you can get out and smack tons of hogs… nice and quietly.

LikeLike

So I have finally had the ability to do some testing with my above mentioned piston guns…

PWS 300 blackout piston 10.5″ barrel Factory complete upper and PWS lower that I used my prefered parts for. The gas block in not adjustable. It is a long stroke piston system which has a rod off from the BCG. The buffer spring is a JP silent capture spring with a maxim defense cheek weld “buttstock”. The JP spring is the standard weight, not light or heavy. Surefire suppressor for now till i get my omega TI our of jail. Shooting both 147gr. FMJ Supers and 220 Subs from Gorilla ammo Co. Both round cycle flawlessly. I sighted it in with the Supers and hold up approx 1″ at the 50 yrd line and 4-5″ at the 100 yrd line when shooting subs. Tried my 12″ steel that’s out to 150, but nothing consistent.

Couldn’t as for a better battle rifle. Testing complete.

As for my other— I decided to do a 100% custom 300 blackout piston gun. Needs just one adjustment. Let me explain. It is very similar to the above. 10.5″ faxon barrel. Adams arms ultralight pistol length 300 piston kit. Maxim defense buttstock/cheekweld. This one has a heavy weight spring, but I think I can change that when I make the adjustment. The upper and lower receiver sets are from SLR rifle works. If you haven’t seen these, then look them up. Most beautiful set I could find. The hand guard is an SLR Helix custom order with full top and bottom rails. The specs for the inside of the rail on the hand guard should have worked. Note- what I had to do to make this work was bring the rifle to a machine shop and have them plane down the barrel nut so that the piston would fit. The shop did a fantastic job and no issues with the barrel nut. Sorry don’t have pictures, but if someone really wanted to know I could pull it apart and may have to anyways. So when I put it all together the inside of the rail seemed very snug on the piston and gas block. But when I removed the BCG and rocked the rifle up and down the piston did freely slide. All in all I think that I need to ‘bore’ out a portion of the inside of the rail/handguard very slightly to smooth out the cycling. I do see marks on the piston from the obvious rubbing, so it would only make sense that there is some slight restriction there. But with all of that said the SLR with the adams arms kit does cycle both supers and subs suppressed ammo mentioned above! So just one minor modification needed!